RAPID IMPACT COMPACTION (RIC)

Rapid Impact Compaction (RIC) offers an alternative to conventional dynamic compaction, or removal and replacement of material in poor ground conditions.

As the first Australian company to own a RIC, we have years of knowledge and experience with our fleet of specialised equipment RIC 7000 – RIC 9000.

WHAT IS RIC?

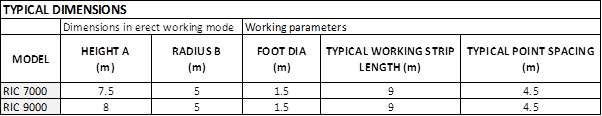

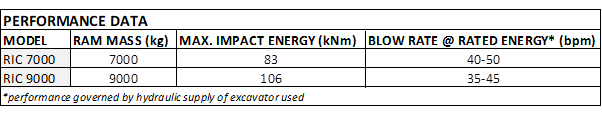

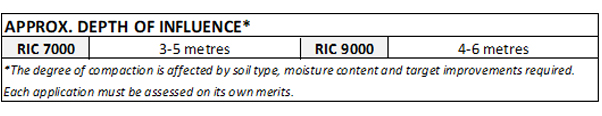

Rapid Impact Compaction is a technique used to increase the bearing capacity of soils through controlled impact. Dependent on ground conditions, the surface compaction can typically penetrate to 6 metres in depth to potentially 10 metres in some situations.

The Rapid Impact Compaction (RIC) unit is mounted on a standard excavator (of suitable size to the RIC weight) which acts as the base unit and provides hydraulic power to the hammer.

ADVANTAGES of RIC

SAFETY – the steel foot remains in contact with the ground at all times improving work site safety conditions and allowing other work tasks to continue. This method can be used in close proximity to existing structures.

TIME – the RIC is mounted on an excavator that can be mobilised on site quickly and easily. The RIC method is much quicker in timing than conventional compacting methods.

CONTROL – the RIC is controlled by the excavator operator. Instrumentation in the cab enables the operator to set target criteria specific to each project, which electronically monitors and control the degree of compaction required.

QUALITY/ACCURACY – an onboard computer records compaction data that can be made available to clients and managers, identifying weak zones and underground obstructions allowing improved accuracy.

APPLICATIONS

- Surface consolidation – varying soil types and conditions

- Waste stabilisation

- Foundation support

- Liquefication mitigation

PREVIOUS PROJECTS

- JACK MADIGAN RESERVE, NEWPORT, VIC

- DENDY PARK GROUND STABILISATION AND REDEVELOPMENT STAGES 1, 2 and 3, BRIGHTON, VIC

- NEXUS INDUSTRIAL ESTATE, DANDENONG SOUTH, VIC

- M5 MOTORWAY, SYDNEY, NSW

- EQUINIX SY5 DATA CENTRE, ALEXANDRIA, NSW

- WOOLOOWARE BAY DEVELOPMENT, WOOLOOWARE, NSW.

- U-TAPAO INTERNATIONAL AIRPORT, RAYONG, THAILAND.

- MCCLELLAND RESERVE SOCCER PITCH, FRANKSTON NORTH, VIC